커피 컵 트레이는 무엇에 사용되나요? — 그들의 기계 생산 뒤에 숨겨진 비밀을 밝혀내다

오늘날 빠르게 변화하는 세상에서 테이크아웃 커피는 많은 사람들의 일상 루틴의 일부입니다. 바쁜 출퇴근 시간이나 오후 휴식 시간 모두 따뜻한 커피 한 잔은 언제나 환영받습니다. 하지만 편리한 커피 구매 뒤에는 작지만 필수적인 물건이 있습니다. 바로 커피 컵 트레이입니다. 커피 컵 트레이의 실제 용도는 무엇일까요? 그리고 커피 컵 트레이 성형기를 사용하여 어떻게 대량 생산될까요?

커피 컵 트레이란 무엇인가?

커피 컵 트레이는 일반적으로 2컵 또는 4컵 유형의 여러 컵을 담기 위해 설계된 성형 펄프 트레이입니다. 생분해 가능하고 친환경적인 종이 펄프로 만들어졌으며, 일회용 제품으로 강하고 실용적이며 지속 가능합니다. 일반적인 색상은 회색 또는 자연 크래프트입니다.

커피 컵 트레이의 주요 용도

테이크아웃 및 배달

음료 배달이 증가함에 따라 컵 트레이는 컵을 안정시키고, 쏟아지는 것을 방지하며 안전한 운송을 보장합니다.

매장 내 픽업 및 다중 컵 운반

스타벅스나 코스타와 같은 커피 체인에서 직원과 고객이 여러 잔을 한 번에 운반할 수 있도록 사용하여 시간과 노력을 절약합니다. 셀프 서비스 핫 음료 스테이션이 있는 편의점에서는 컵 트레이가 더 안전하고 쉽게 다룰 수 있도록 도와줍니다.

브랜드 홍보

로고나 메시지가 인쇄된 맞춤형 트레이는 이동 광고 역할을 하여 포장이 마케팅의 일부가 됩니다.

친환경 포장 대안

전 세계적으로 플라스틱 사용이 줄어들면서, 성형 펄프 트레이는 재활용 가능하고 생분해성이기 때문에 인기를 얻고 있습니다.

그 뒤에 있는 기계 — 커피 컵 트레이 성형 기계

커피 트레이의 대량 생산은 펄프 성형 포장을 위해 설계된 완전 자동 기계인 커피 컵 트레이 제조 기계에 의존합니다. 이 과정에는 다음이 포함됩니다:

- 펄핑폐지는 물과 혼합되어 고운 펄프로 가공됩니다.

- 형성: 펄프는 금형에서 진공 성형되어 2컵 또는 4컵 트레이 모양으로 만들어집니다.

- 건조: 젖은 트레이는 다층 건조기에서 완전히 굳을 때까지 건조됩니다.

- 열 압착: 트레이는 강도를 높이고 표면을 매끄럽게 하기 위해 열압착됩니다.

- 적재 및 포장: 완성된 트레이는 수량이 세어지고, 쌓이고, 포장되어 배송됩니다.

공정 요약: 폐지 → 펄핑 → 성형 → 건조 → 열 프레스 → 포장

커피 트레이 성형 기계를 사용하는 이유는?

고도로 자동화되어, 적은 노동력 필요

- 펄핑, 성형, 건조 및 열 압착을 하나의 시스템으로 통합합니다.

대량 생산을 위한 높은 출력

- 모델에 따라 일일 생산량은 수천 개의 쟁반에 이를 수 있으며, 포장 공장이나 수출업체에 이상적입니다.

맞춤형 몰드를 지원합니다

- 차 쟁반, 와인 병 홀더 또는 음료 컵 쟁반과 같은 다른 펄프 성형 품목을 쉽게 생산할 수 있습니다.

유연한 트레이 유형

- 한 대의 기계로 금형을 변경하여 다양한 쟁반 크기와 모양을 생산할 수 있습니다.

저자가 추천하는 기계 모델

더 자세한 기능과 옵션을 알아보려면 커피 컵 트레이 제작 기계 제품 페이지를 방문하거나 직접 문의해 주세요.

브랜드: Shuliy Machinery

모델: SL-4000-4X8

용량: 4000개/시간

전력: 95kw

전압: 380V, 50HZ

무게: 7000kg

크기: 3250*2300*2500mm

생산 날짜: 25-40 작업일

운송: 해상 운송

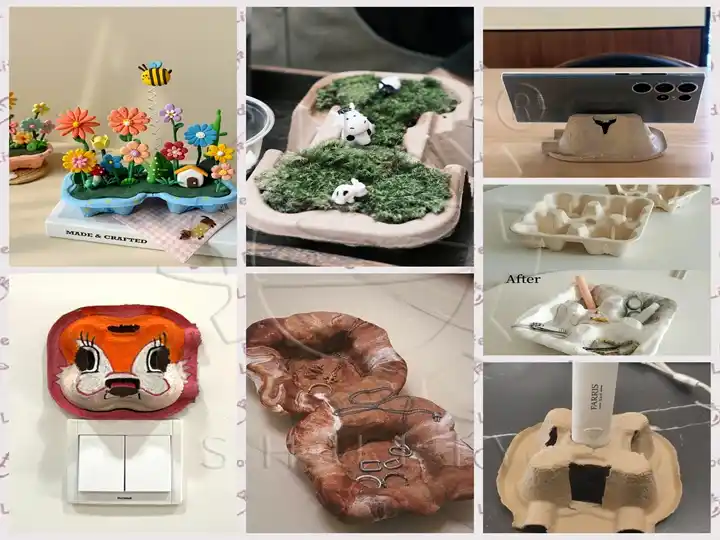

커피 컵 트레이의 놀라운 용도

커피를 다 마신 후에도 트레이는 여전히 가치가 있습니다. 세 번만 재사용해도 탄소 배출량을 80%까지 줄일 수 있다는 연구 결과가 있습니다. 다음은 몇 가지 창의적인 재활용 용도입니다.

가정용 저장

케이블, 문구류, 보석 또는 책상 액세서리를 정리하는 데 좋습니다.

주방 해킹

차 티백, 향신료 봉지 정리 또는 뜨거운 냄비를 위한 열 패드로 사용하세요.

창의적인 DIY 프로젝트

콜라주 아트, 묘목 화분 또는 수공예품에 사용하세요.

더 재미있는 아이디어

애완동물 간식 그릇, 촛대 쟁반, 서랍 칸막이, 전화 거치대 — 모두 간단한 쟁반에서!

신뢰할 수 있는 제조업체 선택 — 슐리 기계

작은 크기에도 불구하고, 커피 컵 트레이는 안전한 운송, 브랜드 이미지 및 친환경 포장에서 중요한 역할을 합니다. 신뢰할 수 있는 트레이 성형 기계는 효율적으로 생산을 확대하는 열쇠입니다.

에코 포장, 음료 용기 지원 또는 펄프 성형 산업에 진입하고자 한다면, 커피 쟁반은 스마트한 출발점입니다.

Shuliy Machinery와 파트너가 되어 함께 더 친환경적인 미래를 만들어 갑시다.