अपने पोल्ट्री फार्म के लिए एक समर्पित अंडा ट्रे उत्पादन मशीन क्यों चुनें?

Many farm owners wonder: Is making egg trays yourself complicated? Does it take a lot of labor and resources? The answer: with the right egg tray production machine, producing trays in-house saves time, effort, and money compared to buying.

Modern fully automatic egg tray production machines handle the entire process—from raw material preparation to finished trays—without much manual work. They are suitable for small, medium, and large farms. In-house production can cut tray costs by 30–50% and allows customization for different egg sizes (starter eggs, regular eggs, or free-range eggs), solving the problem of mismatched trays when buying externally.

This article breaks down the full egg tray production process—from raw material preparation to finished product storage—highlighting the key equipment at each step. It helps you quickly understand what machines are needed and how to choose the right egg tray making machine for your farm.

Main Raw Materials for Egg Tray Production

Egg trays are mainly made from recycled paper, including:

- Waste cardboard (corrugated paper)

- Used newspapers and books

- Paper offcuts and scraps

These materials are widely available and low-cost. Recycling them significantly reduces production costs and supports eco-friendly practices.

Key Tip: After shredding the paper, remove impurities like stones and plastic. This prevents damage to the molding machine and ensures high-quality egg trays.

Step-by-Step Egg Tray Production Process with a Poultry Farm Egg Tray Production Machine

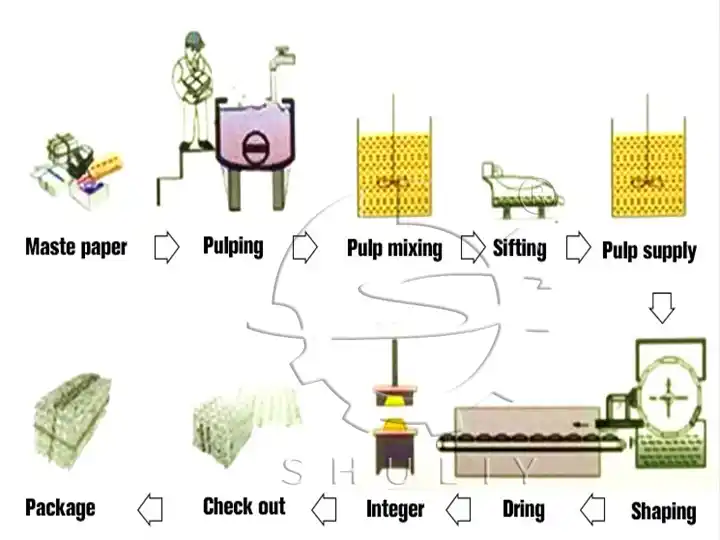

Egg tray production has four main stages: pulping, molding, drying, and packing.

Pulping System

- Raw Material Input: Add waste newspapers, cardboard, or paper cans into the hydraulic pulper.

- Physical Breakdown: High-speed water flow completely separates the paper fibers, creating a uniform pulp.

- Pulp Adjustment: Add water to reach the ideal pulp concentration, usually around 5%, ensuring even molding.

- Additives (Optional): Water-resistant agents (like paraffin) or colorants can be added to improve durability and appearance.

Molding System

- Vacuum Suction: The pulp is transferred to the bottom of the molding machine. A vacuum pump creates negative pressure, pulling fibers evenly onto the mold surface.

- Dehydration & Demolding: Most water is removed during suction. Then, the partially formed wet tray is blown off by compressed air onto a conveyor belt.

- Key Advantage: Ensures standardized grooves and consistent tray size for easy stacking and transport.

Drying Methods

- Brick Kiln Drying: Low cost, suitable for small factories; fuel can be coal or wood.

- Metal Drying Machine: Highly automated, compact, uses natural gas or diesel, and has high thermal efficiency.

- Physical Change: Drying at 150–200°C evaporates water and quickly increases tray strength.

- हॉट प्रेसिंग: Some high-quality trays are hot-pressed for smooth surfaces and precise dimensions.

- Stacking & Counting: Trays are automatically counted, stacked, and packed for easy transport and storage.

- Finished Product Features: Standardized size, strong structure, and both practical and attractive.

Why More Poultry Farms Make Their Own Egg Trays?

- Cost Reduction: Making trays from waste paper saves on purchase and transport.

- Reliable Supply: No dependence on the market; produce trays as needed.

- Better Egg Protection: Good airflow and cushioning reduce breakage.

- Eco-Friendly & Brand Image: Recyclable and biodegradable, enhancing the farm’s image.

- Customizable: Tray size and shape can be adjusted to meet market needs.

Advantages of Using an Egg Tray Machine on Poultry Farms

Cost Control

Uses waste paper or straw, saving raw material expenses.

Stable Supply

Produce trays on demand, unaffected by market fluctuations.

High Efficiency

Automated molding delivers large, consistent output.

Quality Control

Tray thickness, cushioning, and ventilation can be adjusted to reduce egg breakage.

Eco-Friendly

Pulp trays are recyclable and biodegradable, supporting green farming.

Customizable

Tray size can be tailored to egg type and transport needs

Best-Selling Egg Tray Making Machines on the Market

If you want to improve egg packaging efficiency, cut costs, and stay eco-friendly, producing your own egg trays is the best choice. In the poultry farm egg tray machine market, Shuliy stands out with its SL-3*1, SL-4*1, SL-3*4, and SL-4*4 series. These machines offer stable performance and medium-to-high output, producing thousands of trays per hour.

Egg Tray Production Machine – Parameter Reference

| मॉडल | क्षमता | शक्ति | वोल्टेज | वजन | पल्प उपयोग | पानी उपयोग | आकार (मिमी) |

| SL-1000-3X1 | 1000पीसी/घंटा | 38किलोवाट | 380V,50HZ | 2500किलो | 80किग्रा/घंटा | 160किग्रा/घंटा | 2600*2200*1900 |

| SL-1500-4X1 | 1500पीस/घंटा | 38किलोवाट | 380V,50HZ | 3000किग्रा | 120किग्रा/घंटा | 240किग्रा/घंटा | 2800*2200*1900 |

| SL-2500-3X4 | 2500पीस/घंटा | 55किलोवाट | 380V,50HZ | 4000किग्रा | 200किग्रा/घंटा | 400किग्रा/घंटा | 2900*1800*1800 |

| SL-3000-4X4 | 3000पीसी/घंटा | 60किलोवाट | 380V,50HZ | 4800किग्रा | 240किग्रा/घंटा | 480किग्रा/घंटा | 3250*1800*1800 |

| SL-4000-4X8 | 4000पीस/घंटा | 95किलोवाट | 380V,50HZ | 7000किलोग्राम | 320किग्रा/घंटा | 640किग्रा/घंटा | 3250*2300*2500 |

| SL-5000-5X8 | 5000पीसी/घंटा | 95किलोवाट | 380V,50HZ | 8000किग्रा | 400किग्रा/घंटा | 800किग्रा/घंटा | 3700*2300*2500 |

| SL-7000-6X8 | 7000पीस/घंटा | 120क्वाट | 380V,50HZ | 10000 किलोग्राम | 480किग्रा/घंटा | 960 किलोग्राम/घंटा | 3200*2300*2500 |

They feature interchangeable molds to fit different tray sizes, protect eggs during transport, and simplify packaging. Durable, highly automated, and easy to operate, these machines are ideal for farms making eco-friendly pulp egg trays in-house.